4927

St. Croix Ave. Golden Valley, Minnesota 55422

If

you have questions, call -

(763)

521-0217

Contact

Us Return

Contact

Us Return

Forensic and Technical Engineering Investigations for

Production,

Investor, Legal, Adjuster, and

Insurance Offices

Forensic

engineering is the investigation of

materials,

products,

structures or components that fail or do not

operate/function as intended, causing

personal injury or damage to property. The consequences of

failure are dealt by the law of

product liability. The subject is applied most commonly in

civil law cases, although may be of use in

criminal law cases. Generally the purpose of a forensic

engineering investigation is to locate cause or causes of

failure with a view to improve performance or life of a

component, or to assist a court in determining the facts of an

accident. It can also involve investigation of

intellectual property claims, especially

patents. (Wikipedia)

An experienced forensic engineer can be

expected to answer three questions - - -

1. What happened?

2. Why did it happen?

3. How could it have been prevented?

These answers can be expected in the form of a

well-written report and, if called upon, a well prepared verbal presentation.

Our specific expertise is the design, development,

and production, of products and equipment to be used by people. An interesting perspective gained from the variety of

our experience with this people-equipment interface, is how

knowledge in one area can be applied to, and bring insight into other areas.

The fundamental principles of physics do

not change, regardless of the objects to which they are applied. This

variety of experience has allowed us to quickly come up to speed on projects. It gives an added advantage in that we tend

to look at mechanical/electrical situations from a broad perspective, yet retain

the appropriate depth. This is especially characteristic of forensic

engineers with heavy experience in the actual design and production of equipment.

Mr. Berner is credited inventor for 24 U.S. patents, plus some related foreign patents.

Pro bono assistance - Suppose you, as either defendant or plaintiff, believe you have been treated unfairly by the court and would appeal a decision but for lack of funds. If upon review, we agree, we may be able and willing to help out on a no fee basis.

If you have specific questions, please contact John

M. Berner, P.E. at Applications Research, Inc. (763) 521-0217.

If

you need more information on any of these projects, please

click it.

PROJECT

DESCRIPTIONS

ACCUMULATION

CONVEYOR SYSTEM (Computer

simulation) Review and redesign of

installation where manufacturer of the system was unable to offer an explanation for

the system's non-function. Review included analysis, thorough identification

of the problem, and recommendation for correction of

inoperable conveyor system. (Peavey, Con-Agra)

AIRCRAFT

REFUELING VEHICLE FIRE Investigation

for report to insurance company. Conclusions

and recommendations regarding fatal fire in manufacturer’s test facility for aircraft

refueling vehicles. Involved very thorough review and reconstruction of the accident.

We provided absolutely conclusive proof that the cause as failure of a

4" poppet valve subjected to hydraulic

shock. (Brown Minneapolis Tank).

AIRCRAFT

REFUELING VEHICLE FIRE Investigation

for report to insurance company. Conclusions

and recommendations regarding fatal fire in manufacturer’s test facility for aircraft

refueling vehicles. Involved very thorough review and reconstruction of the accident.

We provided absolutely conclusive proof that the cause as failure of a

4" poppet valve subjected to hydraulic

shock. (Brown Minneapolis Tank).

AUTOMOBILE

ACCIDENT

RECONSTRUCTION Past (and continuing)

projects in accident reconstruction analysis involving automotive and fire mishaps. Formal

reports. (Perhaps 10-12 different situations)

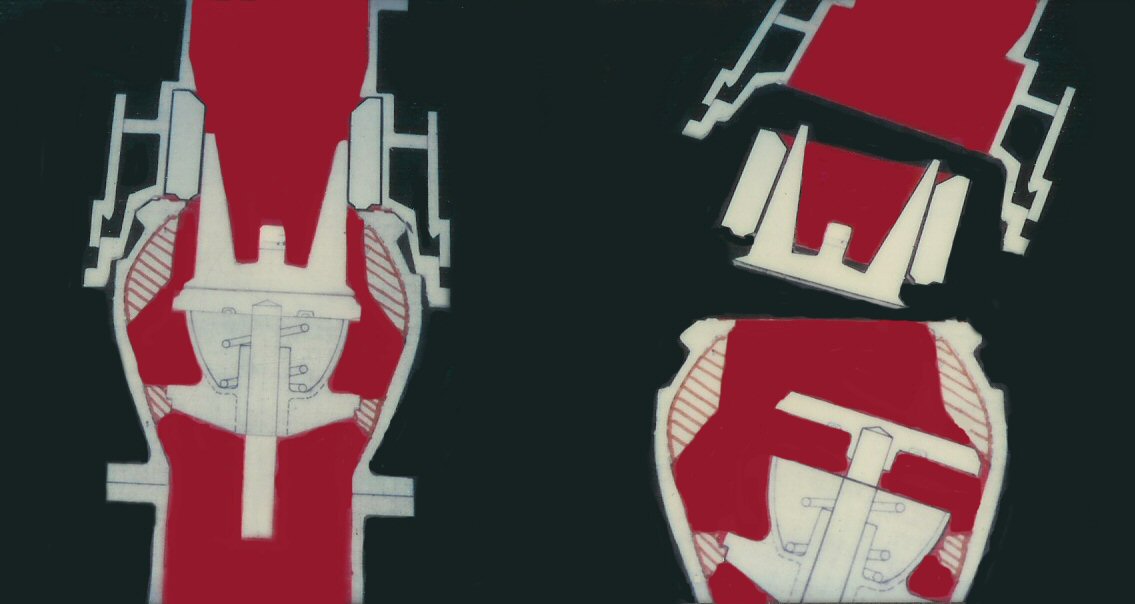

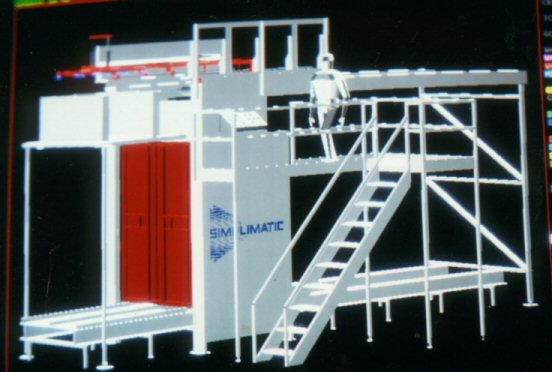

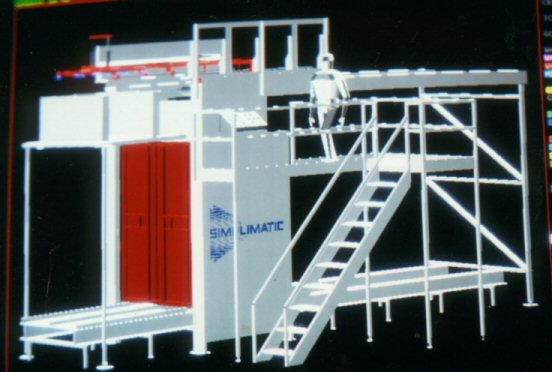

AUTOMATIC

PALLETIZING EQUIPMENT Review of design and structural

configuration of the complete line of palletizing equipment for soft drink

cans. The main industrial design effort was conducted by Mario

Fernandez. The

object was a redesign to streamline the general appearance of the line, yet

avoid any compromising of the structural integrity of the equipment.

Fernandez also developed a suggestion for a new logo and incorporated it

into the renderings of the equipment. This effort also involved review of OSHA issues relating to this equipment.

(Simplimatic)

AUTOMATIC

PALLETIZING EQUIPMENT Review of design and structural

configuration of the complete line of palletizing equipment for soft drink

cans. The main industrial design effort was conducted by Mario

Fernandez. The

object was a redesign to streamline the general appearance of the line, yet

avoid any compromising of the structural integrity of the equipment.

Fernandez also developed a suggestion for a new logo and incorporated it

into the renderings of the equipment. This effort also involved review of OSHA issues relating to this equipment.

(Simplimatic)

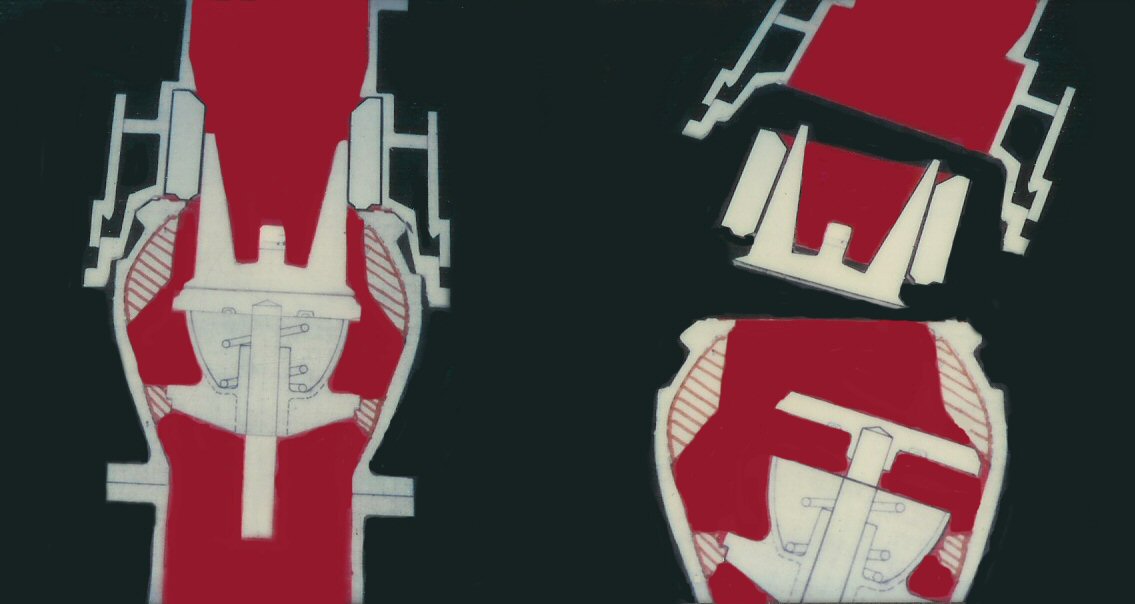

AUTOMOBILE

SUSPENSION ANALYSIS Analysis of automobile

suspension proving standard configuration of a particular U.S. passenger car that did not

meet its own specification for load capacity. Clearly identified problem(s).

Demonstrated spring design under standard load specification allowed rear axles to bottom

out as vehicle still sat in driveway.

AUTOMOTIVE HEATER

Thermodynamic (heat

transfer) investigation and analysis of the effect of restrictions in water flow to

various automotive heaters for various input water and air conditions. Formal report.

This was conducted for the potential manufacturer.

BATTERY CHARGER

Battery charger

investigation and recommendation for potential investment and/or purchase of line. Formal

report, UL review. This was conducted for the potential purchaser and

manufacturer of the line.

BUBBLE SWITCH DESIGN

PARAMETERS This project consisted constructing

mathematical models of a number of typical bubble switch

configurations. One of our conclusions was that the sharp edge where

the bubble met the flat surface was causing very high (destructive) stresses

in the PC laminate material at that point. Also, we were able to

determine that the the problem was worse or most aggravated for the thicker

materials. This was conducted for the manufacturer.

CD PRINTING

MECHANISM DESIGN AND/OR REVIEW Paper analysis of system for

fabrication of compact disk printing system. Developed concept(s) for cost reduction and

streamlining of system and reduction of number of parts. A variety of options were

looked at. Overall effort resulted in about 30% cost reduction of the basic

system. We believe other, more radical changes will amount to even greater cost

reductions with an overall increase in performance. This was conducted

for the manufacturer.

CHEESE

PROCESSING FACILITY Review of cheese processing plant

equipment for problems with equipment. This effort involved a quite

detailed look at th e various items provided for production. Undue wear

patterns caused foreign (metal) particles to be introduced into the finished

product. Result was the product had to be rejected with significant

financial loss to the processor. (Land O' Lakes)

e various items provided for production. Undue wear

patterns caused foreign (metal) particles to be introduced into the finished

product. Result was the product had to be rejected with significant

financial loss to the processor. (Land O' Lakes)

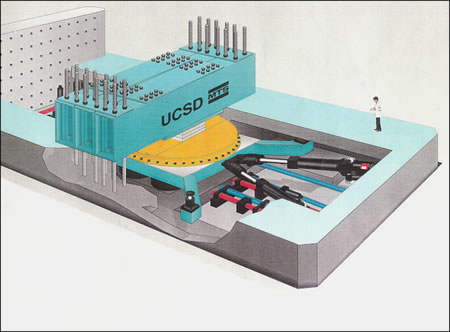

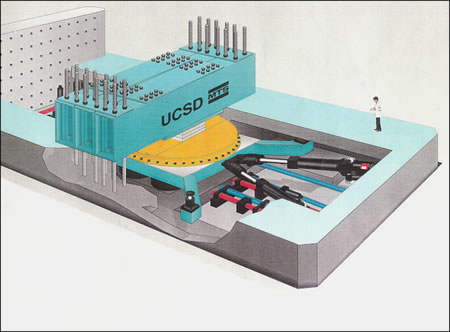

EARTHQUAKE

SIMULATION SRMD (Seismic Response Modification

Device) Review of the safety hazards

and potential failure modes for a large ($14 million) earthquake simulation installation.

Analysis involved review of the hydraulic accumulation system, power distribution system,

and servo control system. (University of California, San Diego and MTS).

AUGUST

'99, UCSD AND CALTRANS California Department of Transportation officially

opened the new Caltrans Seismic Response Modification Device (SRMD)Test Facility

at the San Diego campus. The facility is the first in the world of its kind and

scale, and is designed to test new technologies to retrofit the state’s

longest span bridges.

Equipped

to provide a realistic three-dimensional earthquake simulation, the facility’s

testing table is 16 ft. long by 12 ft. wide, and can move horizontally in all

directions, lift and lower, rotate, and shake at velocities of up to 70 inches

per second. Long-span bridges including the western approach to the Oakland Bay

Bridge, the San Diego-Coronado Bridge, and the Benicia Martinez Bridge are among

those targeted to be retrofitted for earthquake safety through the Caltrans Toll

Bridge Retrofit Program.

ENTERAL

DELIVERY SYSTEM Research effort to come up with various optional

methods to pump medicinal or nutritional fluids into patient during various

hospitalization situations. Involved review of existing systems,

brainstorming of optinal systems, and presentation of best option(s) to client (Sandoz

Nutrition).

ETHYLENE OXIDE

STERILIZER UL approval

preliminary investigation

for ethylene oxide gas sterilizer for use in hospitals. Included review, summary report,

travel to Chicago (Northbrook) to review with U.L. (3M Co.)

FAIRWAY

AERATOR SIMULATION Simulation of golf course fairway aerator

system. This was a device that operated in such manner as to punch holes

in the soil as it moved down the fairway. The process involved a

tremendous load on the transmission and gears that drove the individual

spikes. The output included all the gear loads, bearing loads, some of the

other component stress loads, and a graphical representation of the system as it

cycled. Effort included a quite thorough analysis and report.

FAIRWAY

MOWING VEHICLE

COMPUTER SIMULATION (Computer

simulation) Simulation of golf course

fairway mower system to analyze the problem(s) associated with a phenomenon referred to as

"bobbing". Bobbing is a situation where a reel mower attached to vehicle begins

to vibrate vertically at a resonant frequency which is determined, probably, by the

constants (weight, vehicle speed, tire pressure, cg's, connections, etc.) of the system

and the equivalent spring constant of the interface between the hardware and the ground -

- i.e. the grass/dirt turf pack. By way of this simulation, we were able to evaluate the

relative importance of dampening in the horizontal, vertical, and rotational directions

and the connecting point of the vehicle to the mower(s). An interesting

idea, first

conceived by us and demonstrated with the computer model, was the simulation of the

apparent vehicle/mower pivot connection acting as if it was situated below the surface of

the ground. We referred to this concept as a "virtual" pivot connection since it

could not be achieved unless one devised a (very simple) linkage to create the pivot

point. The computer model was constructed in such manner as to allow changing of almost

all variables as vehicle moved along the ground up to and including drive wheel diameters.

These were variables which could not possibly be continuously modified on an operating

piece of hardware. Computer model and associated graphic was later converted to a MS

Windows-based front end.

FORK

LIFT ACCIDENT (A) Conducted investigation of fork lift

accident fatality. This involved used of a fork truck to support an

operating conveyor in a raw vegetable storage facility in southern

Minnesota. Involved a thorough review of involved mechanisms, their

functions at the time of the accident.

FORK

LIFT ACCIDENT (B) Review of the situation whereby the operator

of a lift truck was discovered (deceased) in place on the tractor with the

engine running, in a large suburban grocery distribution center. In

addition, the fatality was clearly due to head injury. Investigation

involved review of OSHA requirements, environmental situation, fork truck

configuration, measurement a re-layout of the accident site and the position

of that fork truck, as discovered at the accident scene. Client was

insurance carrier.

FREIGHT

DAMAGE ANALYSIS BY TRUCK-TRAILER ACCIDENT

Review of damage to

approximately $800,000 worth of very sophisticated vibration simulation and control

equipment resulting from truck accident. Provided oversite review of repair activities for

insurance company and owners, Lloyd's of London and the Chinese (Mainland) Government.

(Crawford Companies)

GOLF CAR

TRANSMISSION ANALYSIS (Computer

simulation) Review and analysis of golf

car transmission wherein the vehicle speed tended to enter a cycling "surge"

mode when the accelerator was actuated too rapidly. Developed engine-clutch-traction relationships and clearly identified variables that affected the

natural frequency of the system. This led to development of a recommendation and

method for elimination of the problem. Additional effort involved full

stress analysis, including fatigue loading, of all components of the

transmission (Polaris)

HANGAR DOOR

ANALYSIS AND RECOMMENDATION Analysis of loads for all

positions for a vertically lifting door for an aircraft hangar. Report included full

analysis of lifting system power requirement and a general critique of system for function

and safety.

HIGH SPEED

CLUTCH/BRAKE Analysis and design

recommendations for high-speed clutch/brake system. Most thorough analysis of clutch/brake

interaction to that point. Formal report. Presently working on article for

national magazine concerning clutch-brake systems.

INCLINED ELEVATOR

ACCIDENT ANALYSIS Review of accident

with inclined elevator on bank of St. Croix River, involving three adults who sustained serious

injury. Also involved German shepherd dog who jumped free but limped around for

about two weeks. Involved reconstruction and recommendations for prevention of

future mishaps. Formal report, photographs provided. (Client - American Family

Insurance)

INK

MIXING EQUIPMENT Review, evaluation, and certification of

multiple pieces of ink mixing equipment just prior to its preparation for

shipment to India. Client was manufacturer/distributor.

MOBILE ASPHALT

PLANT FIRE Review and reconstruction of

situation leading to fire. Included site visit, photographing of site, interviews with

various individuals and recommendations to prevent future mishaps. Costs to rebuild were

reviewed for fairness and consistency with the reconstruction work performed. (St. Paul

Companies).

MOLASSES

MIXING TANK(s) Complete review and analysis of molasses mixing

tanks. This included thorough stress analysis of the main structure

and the 12 foot diameter circular perforated plates and welds. We took

into account the cyclical (fatigue) nature of the loads as the tanks were regularly

filled and emptied approximately 10 times daily (Arrow

Tank).

MOTOR

FAILURE IN FAN-COIL COOLING UNITS This was an investigation

of the very early failure of motors in a series of fan coil

systems. This involved complete teardown and review of the various

components of the system. Our final report and certification involved description of

our investigation plus clear identification of the cause of the

problem. (City of St. Paul).

MOTORCYCLE

ENGINE Review of components and loads for motorcycle engine.

This included stress loads for crankshaft and recommendations for production.

Client was potential manufacturer.

OIL PURIFICATION TRANSPORT UNIT Complete review from operator

safety standpoint, of a mobile oil purification transport system

design. This include review of all electronic controls and potential

burn hazards, heat flow through unit, and final recommendations.

(Porous Media Corporation)

OLYMPIC SIZED

SWIMMING POOL Swimming pool panel stress

analysis. Involved analysis of various hydraulic load situations comparing aluminum with

fiberglass from both a strength and cost standpoint. Included fatigue analysis of

design. Investigation also involved very interesting review of the natural frequency

of the water mass in various size containers varying all the way from bath tubs to Olympic

sized pools. Recommendations for redesign were eventually incorporated.

(Toro-Gametime Division)

PALLETIZING EQUIPMENT

Review, analysis, and

redesign recommendations for a high volume soft drink can palletizing machine. Work

include re-specification of components in such manner as to improve visual characteristics

of equipment without compromising the actual structure. Use of proper components

allowed actual slimming of the unit(s) while strengthening some of the critical

components. Graphiics were developed around 3D computer models of the machines.

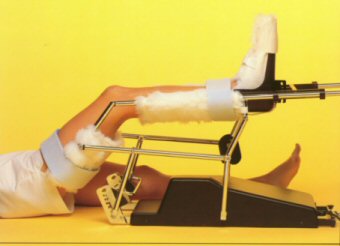

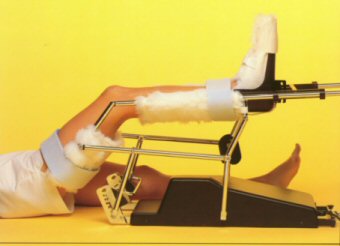

PASSIVE

MOTION EXERCISE DEVICE COMPUTER SIMULATION (Computer

simulation) This was a follow up, by a few

months, on work we had completed as p art of our design of the original machine. Review of linkages and creation of a graphical computer

simulation of the motion of the device. Computer program was created that

not only read back the loads on all the pivot points, but the linkage loads and

the bearing lives at the expected loads and speeds. In addition it was set

up so as to allow the client to enter the applied loads and the speeds involved

in the various situations. While we had completed a number of these

calculations earlier, the program allowed the client to easily change all the

inputs and retrieve answers, by screen or printout, for the loads and lives on

all linkages and bearings in the system. (EMPI)

art of our design of the original machine. Review of linkages and creation of a graphical computer

simulation of the motion of the device. Computer program was created that

not only read back the loads on all the pivot points, but the linkage loads and

the bearing lives at the expected loads and speeds. In addition it was set

up so as to allow the client to enter the applied loads and the speeds involved

in the various situations. While we had completed a number of these

calculations earlier, the program allowed the client to easily change all the

inputs and retrieve answers, by screen or printout, for the loads and lives on

all linkages and bearings in the system. (EMPI)

PONTOON

HANDRAIL INVESTIGATION Based upon our experience with handrail

design, we were selected to evaluate a number of different configurations for

handrails of pontoon boats. The object of this was to minimize the

potential for damage to hands and fingers of the passengers - especially young

ones. This was accompanied by a complete report.

PROJECT

INVESTMENT ANALYSIS This was a computerized system for

inclusion of all the company's engineering projects into an overall combined return on

investment analysis. This was done because specific

engineers recognized that, due to erroneous tax treatment, all new product

programs were being unfairly compared to alternative investments. In addition, the cost assigned to various programs

were regularly subjected to whimsical (fast and loose) estimates based more upon

USWAG figures than on factual data. This helped to put engineering

cost estimates on a more legitimate, professional, footing (Toro).

ROOF

LOUVER INSPECTION - CERTIFICATION Effort involved comparison of

existing louver system with the standard for that particular building product

and to certify its compliance. Report was presented. Client was the

manufacturer

SAW

- RADIAL ARM A carpenter severed part of his hand while

using a radial arm saw on a job site. Although the saw was set to cut window

headers, the carpenter claimed the saw lurched rapidly toward him as he reached

for the handle. Post-accident site investigation was not possible. We were

retained because one of our strengths is the design and test of consumer grade

power equipment. Careful examination revealed that a foreseeable

distortion in the plastic motor housing unit would allow the saw to come out of

its locked vertical position. The manufacturer later incorporated the type

of restraining device recommended by us. Perhaps, the manufacturer should

have spent time with us before this happened, rather than after.

SAW SWITCH DESIGN Review of accident involving circular saw

switch wherein we clearly identified the failure mode as one whereby the

"off" contact was designed too close to the "on"

contact. This led directly to the saw's switch not cutting power to the

unit when it was switched to the "off" position.

SNOW

EQUIPMENT - VARIOUS DESIGN

ANALYSIS EFFORTS Five or six various clutch,

gear, or structural analysis efforts to assist Toro engineering people with snow equipment

projects. Mr. Berner, of this office, was a major contributor to Toro's

present snow equipment design. This included the

original two-stage snow throwers, plus, origination of Toro's "Power

Curve" concept - the "star" feature of its present single stage

snow thrower lines.

STAIRWAY SAFETY

STUDY AND FOR U.S. GOVERNMENT As part of

the government sponsored development of a concept for assisting the individuals to more safely climb up or down

stairs, a study was conducted, involving

the negotiation of stairways for the elderly and handicapped, The

device essentially amounts to a walker which is affixed to one side of a stairwell and

makes it possible to secure one's position all the way up and all the way down a stairway

so as to avoid the head-over-heel fall. This is presently installed in about 50 - 55

homes around the Twin Cities metropolitan area. As result of work on

this study, plus other efforts, we have gained considerable expertise in assistance technology related to

safely moving people.

TISSUE

EXPANDER INVESTIGATION Complete review of tissue expander

characteristics for insurance company prior to authorization for payment of

claim. This included leak testing of samples provided, observation of

pump-infusion system, and review of fabrication manual for the

expanders. Object was to identify where an obvious cut occurred in the

tissue expander surface. (St. Paul Companies).

TOY GUN MISHAP

Review of situation whereby

toy gun stuck in eye of a four year-old child by a five year-old child resulted in

destruction of the lens and iris. Demonstrated by medical photography techniques that the

incision in the surface of the eye exactly matched the configuration of the tip of the

flash suppressor of the (quite accurate) scale model of a 1967 version M-16 U.S. Army

rifle. Effort involved quite thorough investigation of the toy and the actual weapon upon

which it was based. Result based upon demonstration that all other toy guns had blunted or

rounded tips, plus observation of small children using toy guns.

TRACK MAINTENANCE

VEHICLE FIRE INVESTIGATION

Investigation for insurance

carrier of fire involving $550,000 track maintenance vehicle and about $350,000 repair

expense. Questions were raised concerning costs associated with level of effort required

for completion of system. Identified about $150,000 of unreasonable, expenditure.

Accounting office that missed this was not happy with us. However, the

insurance adjuster was quite pleased. (Insurance

consortium)

TRANSIT

STORE SEAT-DESK MECHANISM This project involved investigation

of, and redesign of a desk chair mechanism such as to allow a physically

handicapped individual to function in a manner that accommodated her

limitations. This involved a balance system to make it easy to lift or

lower the work surface of the work station along with all the normally

required equipment (approx 100 lbs). Work was performed as a

sub-project to overall project for the Metropolitan

Transportation Commission.

TRANSMISSION

ANALYSES 3 speed geared transmission

analysis - gears, bearings, shafts. Complete AGMA analysis for both stress and durability.

This was a three dimensional analysis, in that the gear and bearing forces were

analyzed in the X, Y, and Z directions, combined to determine resultants, and

applied to the appropriate gears, shafts, and bearings. This is generally

considered a fairly difficult analysis and beyond the capability (and interest)

of most engineers. Formal report. (Have performed this for Toro on multiple occasions).

TRANSMISSION

INFINITELY VARIABLE This investigation involved the complete

teardown and review of each component of the mechanism of the standard Zero-Max

infinitely variable speed control. This included stress analysis, fatigue

considerations, and recommendations. (Zero-Max Industries)

UTILITY VEHICLE

TRANSMISSION ANALYSIS 3 speed geared transmission

analysis - gears, bearings, shafts. Complete AGMA analysis for both stress and durability.

3 dimensional load analysis for all shafts and bearings in all three speeds for expected

input torques. Formal report.

WATER SOFTENER

AUTOMATIC VALVE

Analysis of high volume home

water softener system. Field failure data was analyzed, compared with lab test data, and

summarized. Summary included thorough review of components and recommendations for future

design and test procedures. Involved thorough Weibull distribution statistical

analysis. (Ecodyne)

WHEELCHAIR WHEEL FABRICATION SYSTEM Analysis of wheel chair

wheel fabrication system for cost improvement and optimization of labor. Effort

included analysis of tooling costs and design changes into a return of investment

analysis. (Theradyne)

WIND TURBINE

Preliminary studies, design,

and drawings and prototype construction for roof-mounted wind turbine (augmented

horizontal Darius). This effort was an investigation of the possibility of using

either man made (buildings etc.) or natural structures such as low hills, tree lines etc.

to augment the flow of air into a wind energy device. The results of this effort

look quite promising, especially in the northern climates if the power is used to directly

operate heating devices. This is because infiltration type heat loss in a structure

is closely related to wind speed. Conversely, so is heat gain if provided by the

wind energy device The match-up makes for interesting possibilities in northern

climates and/or seashore locations.

WINDOW FRAME

REDESIGN Redesign and recommendation

for a window frame system for apartment building windows which would reduce the problem of

young children pushing out the screen and falling through. Redesign based on

absorption of running child's kinetic energy. We were able to identify

and test at least four separate systems for accomplishing this goal.

(Attorney)

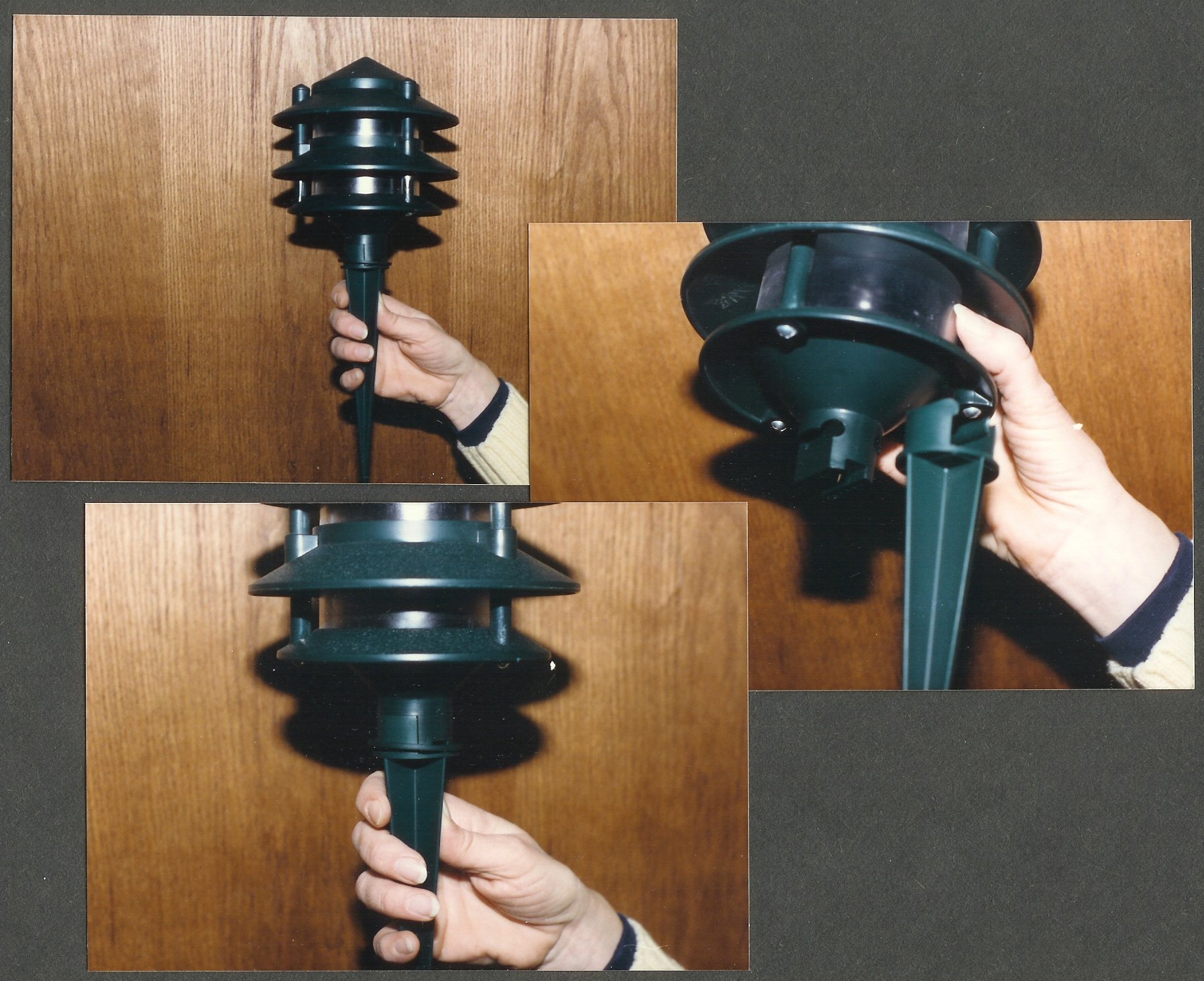

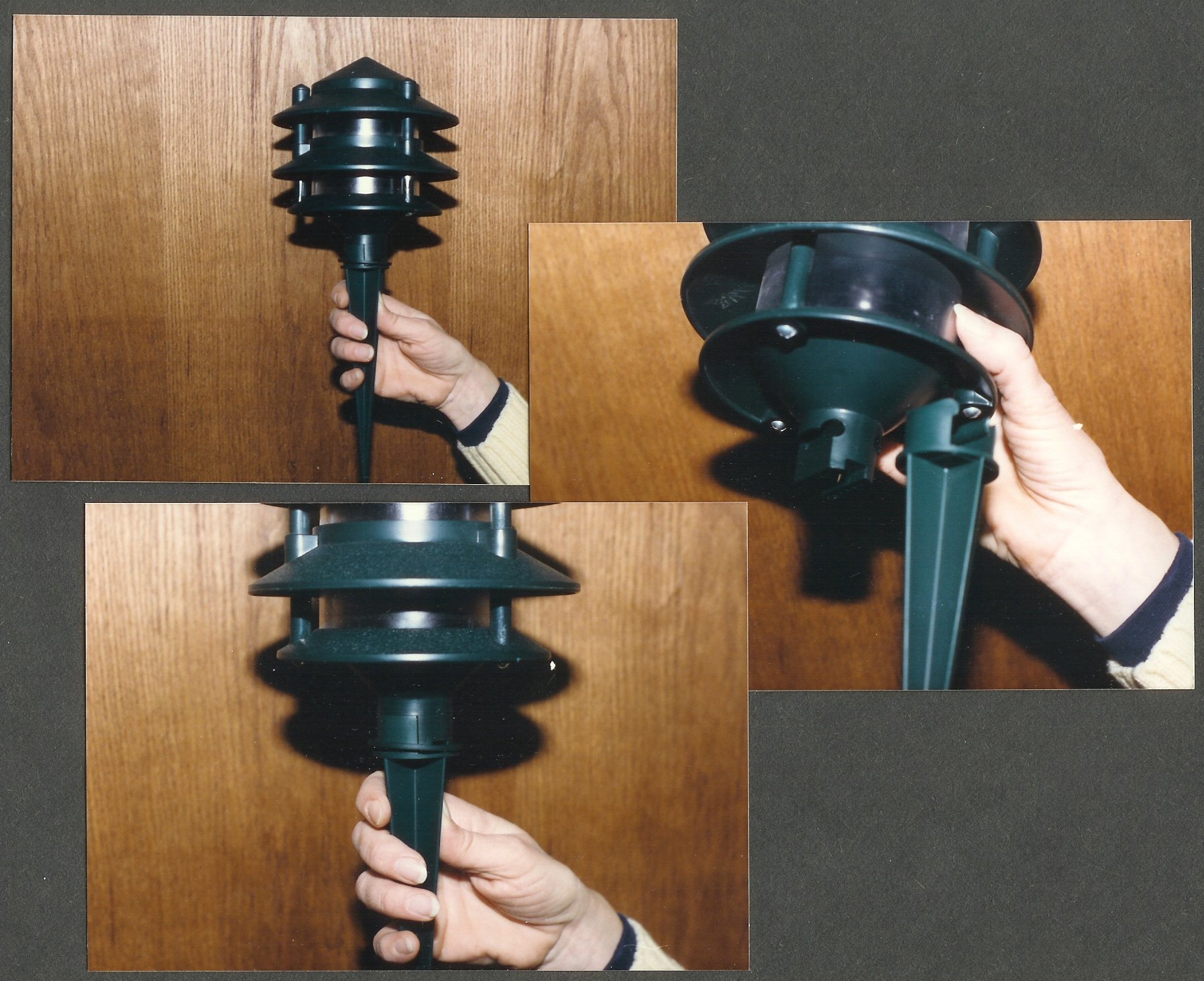

YARD LIGHT

CONCEPT Sole originators of concept for joining cord

to light for a yard light manufacturer which allowed production of lights

without infringing upon pre-existing patent(s). Project was conducted on an

emergency basis for a small electrical component manufacturer by the name of L &

L. Its manufacturing chief assigned us to this effort to overcome a patent

infringement injunction. Successful follow-up by others company led to company's

(L & L) purchase by Toro. The product line developed around this concept

eventually became the nucleus of Toro's Home Products Division.

APPLICATIONS

RESEARCH, INC.

4927 St. Croix Avenue, Golden Valley, MN 55422

If you have questions

call - (763) 521-0217

Contact Us by E-mail

Visitors

AIRCRAFT

REFUELING VEHICLE FIRE

AIRCRAFT

REFUELING VEHICLE FIRE

art of our design of the original machine. Review of linkages and creation of a graphical computer

simulation of the motion of the device. Computer program was created that

not only read back the loads on all the pivot points, but the linkage loads and

the bearing lives at the expected loads and speeds. In addition it was set

up so as to allow the client to enter the applied loads and the speeds involved

in the various situations. While we had completed a number of these

calculations earlier, the program allowed the client to easily change all the

inputs and retrieve answers, by screen or printout, for the loads and lives on

all linkages and bearings in the system. (EMPI)

art of our design of the original machine. Review of linkages and creation of a graphical computer

simulation of the motion of the device. Computer program was created that

not only read back the loads on all the pivot points, but the linkage loads and

the bearing lives at the expected loads and speeds. In addition it was set

up so as to allow the client to enter the applied loads and the speeds involved

in the various situations. While we had completed a number of these

calculations earlier, the program allowed the client to easily change all the

inputs and retrieve answers, by screen or printout, for the loads and lives on

all linkages and bearings in the system. (EMPI)